2025-12-26

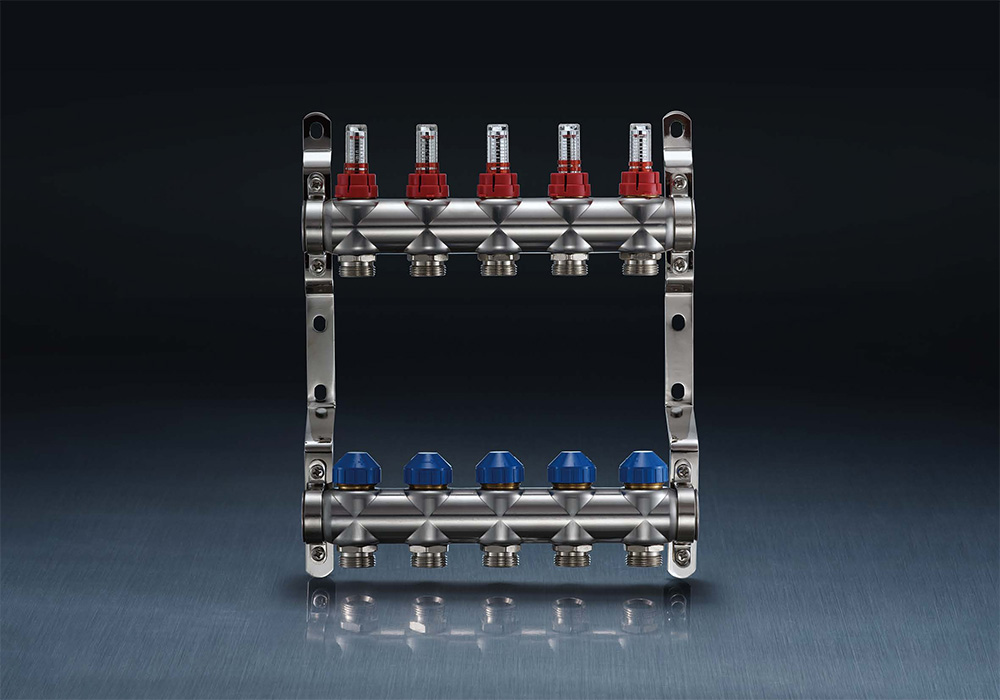

Stainless steel manifolds are widely used in industrial, commercial, and residential fluid systems. They serve as central distribution points, directing the flow of water, gas, or other fluids to multiple outlets. The choice of materials in stainless steel manifolds affects their durability, corrosion resistance, and overall performance. Understanding these materials from multiple perspectives helps in selecting the right manifold for specific applications.

Stainless Steel Alloys

The primary material in stainless steel manifolds is the stainless steel alloy itself. Common types include 304 and 316 stainless steel, which are chosen for their corrosion resistance, strength, and compatibility with fluids.

304 stainless steel is widely used in systems where exposure to water or mild chemicals occurs. It provides adequate resistance to rust and mechanical wear. In more demanding applications, such as systems exposed to saltwater, acidic fluids, or high temperatures, 316 stainless steel is preferred due to the addition of molybdenum, which improves resistance to corrosion and pitting. The selection of the stainless steel grade directly affects the manifold's lifespan and suitability for different fluid types.

Sealing Materials

Stainless steel manifolds often require sealing components to prevent leakage at connections or joints. Common materials for seals include rubber, silicone, and PTFE (polytetrafluoroethylene).

Rubber and silicone seals provide flexibility and maintain tight connections under moderate pressure and temperature ranges. PTFE is often used in applications with higher temperatures or aggressive fluids due to its chemical resistance and stability. The choice of sealing material depends on the type of fluid, operating temperature, and pressure conditions. Proper seals complement the stainless steel structure and ensure reliable operation without leaks.

Fasteners and Fittings

In addition to the main stainless steel body, manifolds incorporate fasteners, nuts, and fittings, which are often made from stainless steel, brass, or compatible alloys. These materials are chosen to prevent galvanic corrosion and maintain mechanical integrity.

Stainless steel fasteners are preferred in cases because they match the corrosion resistance of the manifold body and provide uniform expansion and contraction under temperature changes. Brass fittings are sometimes used for specific connections, particularly when interfacing with non-stainless components or for ease of threading. The material selection for fasteners and fittings ensures that the entire manifold system remains stable, durable, and safe over time.

Coatings and Surface Treatments

While the primary material is stainless steel, additional coatings or surface treatments may be applied to improve performance. Passivation, for example, is a common chemical treatment that enhances the naturally occurring protective oxide layer on stainless steel, reducing the risk of corrosion and surface contamination.

Other treatments include polishing, electropolishing, or protective coatings that provide smoother surfaces, reduce friction, and improve cleaning efficiency. These treatments are particularly useful in manifolds used in food processing, pharmaceutical, or water distribution systems where hygiene is critical. Coatings and surface treatments complement the choice of base material, extending the manifold's service life and maintaining reliable performance.

Stainless steel manifolds are composed of carefully selected materials to ensure durability, corrosion resistance, and safe fluid handling. The main body is made from stainless steel alloys, such as 304 or 316, chosen according to the fluid type and operating environment. Sealing materials, including rubber, silicone, and PTFE, provide leak prevention at connections. Fasteners and fittings, often stainless steel or brass, maintain mechanical stability and prevent galvanic corrosion. Coatings and surface treatments, such as passivation and polishing, further enhance corrosion resistance, hygiene, and overall performance. Considering these four aspects of materials allows engineers, manufacturers, and end-users to select stainless steel manifolds that meet specific operational requirements and maintain long-term reliability.