2025-06-06

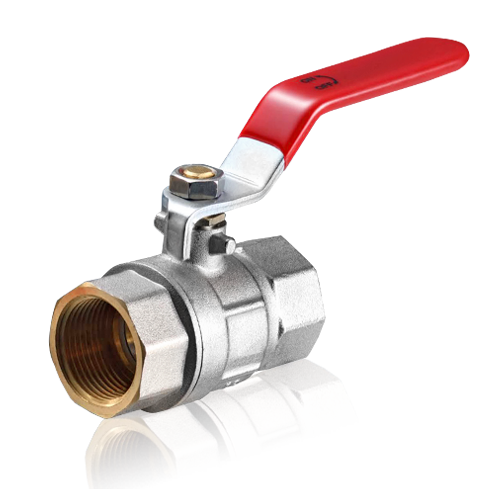

Brass ball valves are essential components used widely across many industries, including plumbing, HVAC, automotive, and manufacturing. Their primary function is to control the flow of liquids or gases by using a spherical ball with a hole in the center. When the valve handle turns the ball so that the hole aligns with the flow, fluid passes through; when turned perpendicular, the flow stops. Due to their durability, corrosion resistance, and ease of operation, brass ball valves have become a popular choice for various applications.

1. Based on Connection Types

One of the considerations when selecting a brass ball valve is the type of connection it uses. The connection type determines how the valve attaches to the piping system and influences installation methods and compatibility.

Threaded Ball Valves: These valves feature threaded ends—typically either male or female National Pipe Thread (NPT). Threaded connections are common in plumbing and residential systems because they are easy to install and replace without special equipment. However, care must be taken to apply proper sealing tape or compound to prevent leaks.

Socket Weld Ball Valves: Socket weld valves have a socket into which the pipe is inserted and then welded, providing a strong, permanent joint. They are often used in high-pressure or high-temperature applications and are more common in industrial settings.

Flanged Ball Valves: These valves use flanged ends with bolt holes for connecting to flanged piping. Flanged connections provide strong, leak-resistant joints suitable for large-diameter pipes or systems where valves may require regular removal for maintenance.

Compression Ball Valves: With compression fittings, these valves are popular for smaller pipe sizes and applications where ease of installation is paramount, such as domestic water lines.

2. Based on Valve Configuration

Brass ball valves come in different configurations that affect their functionality and flow control capabilities:

Two-Way Ball Valves: The common type, these valves have two ports—an inlet and an outlet. They are used for simple on/off flow control, suitable for a wide range of applications.

Three-Way Ball Valves: Featuring three ports, these valves allow flow to be diverted between two different outlets or mixed from two inlets. They come in two main configurations: L-port and T-port. L-port valves switch flow between two outlets, while T-port valves can mix or distribute flow among the ports. Three-way valves are common in HVAC systems, chemical processing, and irrigation.

Multi-Port Ball Valves: Beyond three-way, some applications require four-way or more complex valves. These valves enable even greater control and routing options but are less common and typically used in specialized industrial settings.

3. Based on Handle Types

The operation of brass ball valves depends on the handle mechanism, which can affect ease of use and precision.

Lever Handle: Lever handles are the common and provide quick, quarter-turn operation to open or close the valve. They offer a clear visual indication of valve position and are suitable for general applications.

Gear Operated Handles: For larger valves or those requiring precise control under high pressure, gear-operated handles provide mechanical advantage, making it easier to turn the valve. These handles are more common in industrial applications.

Electric or Pneumatic Actuated Handles: For automated systems, brass ball valves can be fitted with actuators controlled remotely or by sensors. This option is ideal for large-scale industrial processes or where remote operation is necessary.